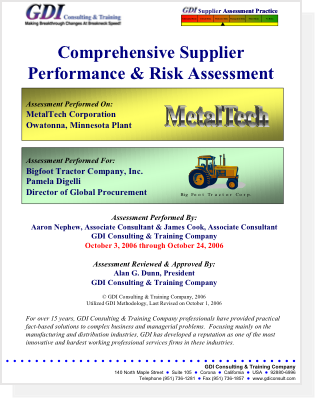

Why Your Company Needs To do a Better Job of Supplier Evaluation… 5 BIG Reasons

- Global Suppliers are Farther Away

- Lead Times are Longer

- JIT Eliminates Buffers

- Less Inventory is In the Pipeline

- Suppliers are Harder To Get To Know

"Proactive & thorough due diligence of critical Suppliers is a new necessity in the global supply world where distances can be great, supply complexities can be even greater & consequences of poor supply can be devastating to the bottom line."

- Alan G. Dunn